Detailed plastic profile processing is our value proposition to our customers along with high quality custom solutions.

One of the primary advantages of an extruded plastic profile is the possibility of obtaining a finished product in one manufacturing process. For this reason special plastic profiles processing capabilities are essential when additional profile applications are necessary during the extrusion process.

Our experience and flexibility has enabled us to implement several processes in our extrusion plants to optimize costs of the finished profile. In order for special plastic profiles processing can be executed directly and continuously in the extrusion process, we dispose of specific automatic machinery that are synchronized to the overall plant.

We often utilize machinery to process plastic materials that are engineered and constructed appositely to obtain highly efficient customized plastic profiles. In order to manufacture complex products, we utilize special machinery to process plastic materials that can be applied directly on the plastic profile after the extrusion phase.

Processing Plastic Materials

Follows a list of various types of processes applied on plastic profiles. We are also able to execute different applications and treatments according to the designed function of the extruded profile.

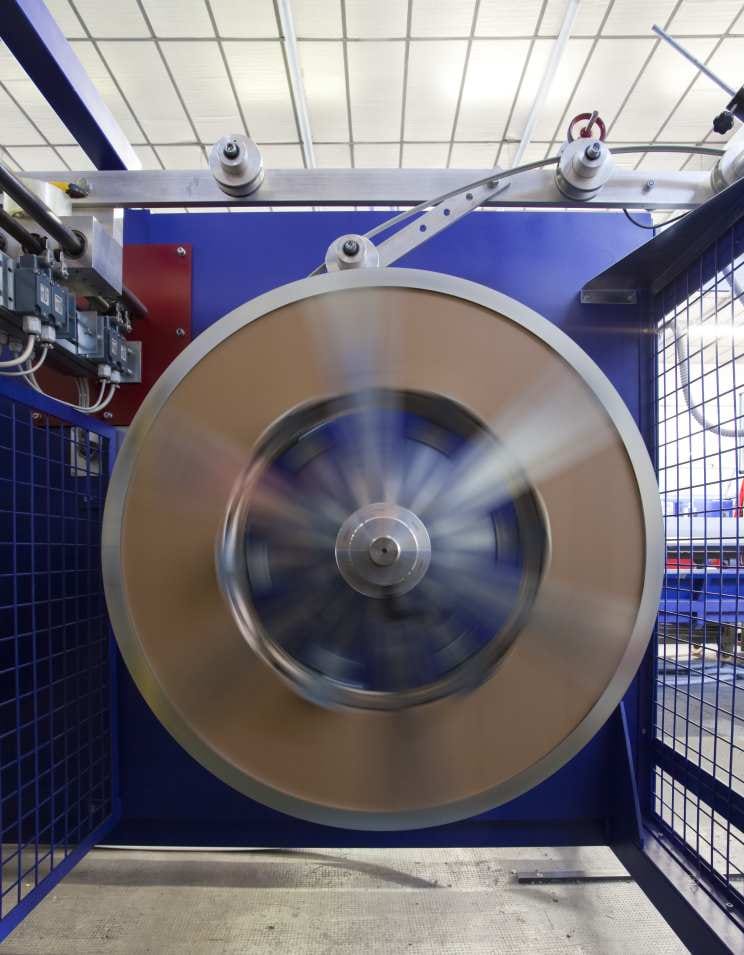

Processing Plastic Materials: mechanical

- Cut to length with different types of blades

- Guillotine cutters

- Multiple inclined cutting

- Boring and shearing

- Punching

- Milling

Processing Plastic Materials: heat processing

- Heat Bending

- Folding

- Heat welding

Processing Plastic Materials: surface treatments

- Multiple hot stamping finishes

- Surface polishings

- Surface opacification

- Laser markings

- Various bi-adhesive applications

- Primer applications

- Protective films

- Various embossing textures

Processing Plastic Materials: non-plastic coextrusions

Inside the plastic materials it is possible to insert:

- Aluminum foils for aesthetic purposes

- Metal profiles for structural uses

- Magnets

- Filaments

- Paper

Other Processing Plastic Profiles

- Assembling

- Custom packaging

- Special requirements

Advantages for the customer

- Dedicated engineer that manages the complete process

- Finished product with established costs and delivery times

- Detailed profile or gasket customization

- Facilitated profile assembly with other components