Plastic profiles and gaskets in appliances for washing, drying, ironing, cooking, cooling, or cleaning

Gaskets and plastic profiles for appliances are essential for improving energy efficiency and the performance of these products, whilst maintaining appealing finishes and designs, as well as containing costs.

Plastic profiles for appliances contribute to achieving the required energy regulations concerning acoustic performance and reduction of the energy consumption. At the same time, they contribute to containing costs of the final product.

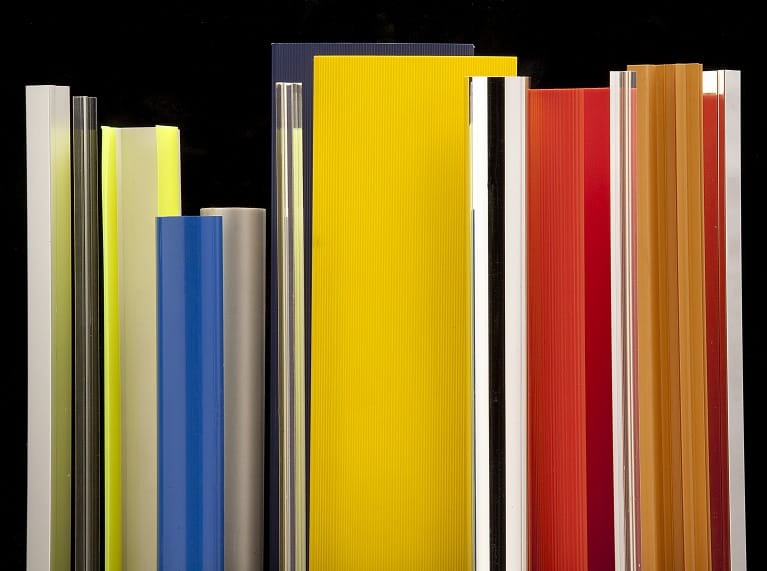

The new extrusion production processes coupled with the mechanical properties and aesthetics of techno-polymers make it is possible to produce plastic profiles for appliances that can substitute metal components. The primary advantages are lower costs, increased insulation properties, and weight reduction. This is also made possible because one of the advantages of the extrusion process is to manufacture a finished product in a single passage.

Starting from the requirements of each type of appliance, we develop the project in co-design with the customer. We then proceed to the industrialization step and evaluate the most suitable plastic materials. In particular, we verify the thermal, acoustic, and electrical insulation properties. We also consider the ecological aspect, as we select recyclable materials with a low environmental impact.

Gaskets and plastic profiles for appliances are manufactured in rigid and flexible materials, co-extruded, and armed with metallic components.

For this market segment we can provide custom logistical solutions according to supply chain requirements.

The following, is a partial list of gaskets and plastic profiles for appliances

- Handles

- Insulating gaskets

- Refrigerator gaskets

- Gaskets for refrigerators

- Sealing gaskets

- Gaskets for high temperatures

- Frames

- Profile gasket holders

- Handles for refrigerators

- Bumpers

- Sheath coverings

- Sealing gaskets

- High impact casings

- Sesthetic external profiles

- Grid profiles for refrigerators

- Profiles for shelves

- Profiles for hoods

- Gaskets for doors

- Slit sealing profiles

Advantages of plastic profiles and gaskets for household appliances:

- Easy assembly

- Easy to clean

- Energy efficiency recovery

- Custom made

- Low density

- Hermetically sealed

- Acoustic sealing

- Electrical insulation

- Resistant to high or low temperatures

- Resistant to common detergents

- Water resistant

- Custom finishes: transparent, alluminum, trasnlucent effect or frosted

- Low thermal conductivity

- Materials in accordance with specific industry regulations

- Recyclabe materials

Submit your request for an extruded plastic profile

Fill out the form to request a quote or personalized consultation.

Discover how we can help bring your ideas to life.